Transparency as a Lever: For Miele, Sustainability is an Integral Part of Good Engineering

In many development projects, a product’s sustainability is determined during the early development phase. It is precisely at this stage that the necessary transparency is often lacking: which materials and joining techniques result in lower carbon dioxide equivalents (CO₂e)? How can the level of circularity be increased without undermining functional, mechanical or economic requirements? For Miele, the focus was therefore on making clear early on where the major levers lie – not with an excess of technical detail, but with clear guidance that may be integrated into everyday development and enables robust decisions across the entire lifecycle.

This motivation is decisive for the Sustainable Lifecycle Engineering (SLE) project: moving away from gut feeling, towards consolidated knowledge about the impacts of design and engineering decisions – particularly regarding materials and joining techniques as key factors for repairability and recyclability.

Existing Miele Design Guidelines and Life Cycle Assessments (LCAs) were compared with SLE solution approaches developed jointly in the SLE consortium and consolidated on the basis of a compact, practice-oriented recommendation for sustainable product development.

Five fields of action for sustainable product development

Five fields of action were derived that reflect the Miele sustainability strategy: user-oriented sustainability, longevity, repairability, energy and efficiency optimisation, as well as sustainable material selection.

“It was important to us that we do not take decisions away from people, but enable them – with clear transparency on CO₂e and circularity right from the concept phase.”

Max Wagner, Director Sustainability Miele

The aim is for developers to be able to assess early on which choice – for example recycled material vs. virgin material – is the best option from a sustainability perspective, while simultaneously considering physical, mechanical and economic requirements. The recommendation is intended as a ‘soft’ guideline: it provides context and guidance without pre-empting decisions.

“It was important to us that we do not take decisions away from people, but enable them – with clear transparency on CO₂e and circularity right from the concept phase”, says Max Wagner, Director Sustainability Miele.

Identify high-impact components in a targeted manner

Within the field of action ‘sustainable material selection’, both existing and future products are examined with regard to CO₂e and circularity levels. Particular attention is paid to high-impact components (in terms of their influence on CO₂e and circularity levels, not impact toughness): assemblies whose material and design choices significantly influence the environmental footprint and circularity.

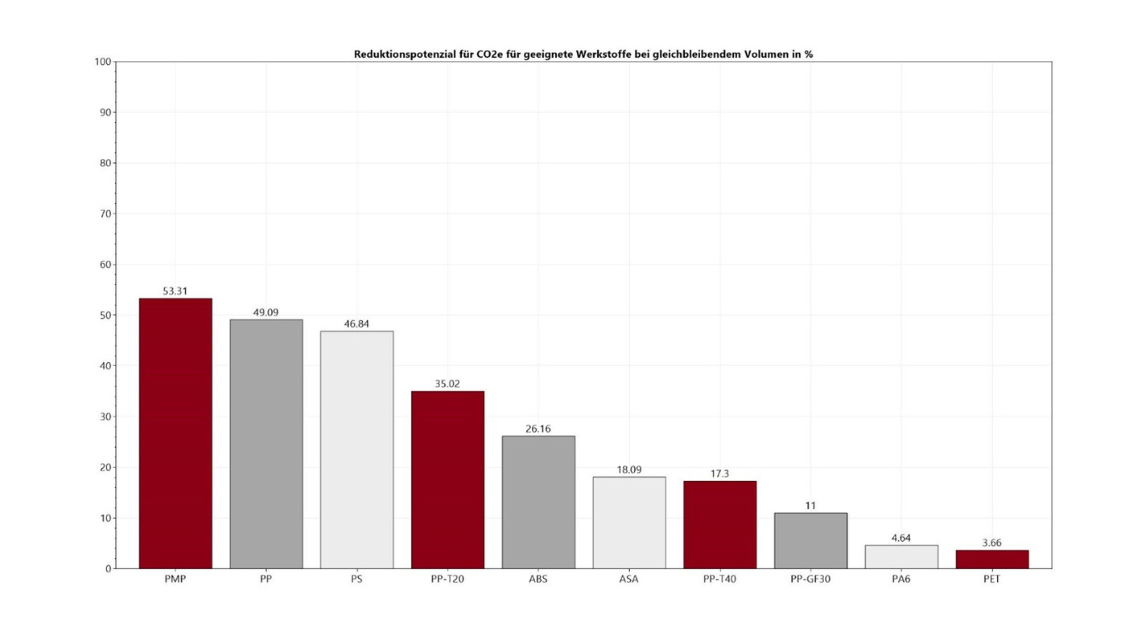

Through an in-house development, these large-lever components can be automatically identified, and CO₂e reduction potential can be specifically determined while prescribing defined properties, e.g. Young’s modulus, tensile strength or density, for a constant component volume.

Results and Benefits

From the interplay of SLE knowledge, Miele guidelines and LCA data, a tangible development recommendation has emerged that combines sustainability with engineering reality. It accelerates the assessment of key questions – such as when comparing recycled and virgin materials – whilst simultaneously highlighting typical trade-offs: mechanical properties, processability, costs, quality variations.

“Transparency on CO₂e and circularity across the entire lifecycle, even at component and sub-component level, is enormously helpful in identifying high-impact levers.”

Christian Neese, Project Manager Miele

A possible result is simplified material diagrams, for plastics for example, which systematise the selection process. They visualise where recycled materials save CO₂e compared with virgin material and how circularity levels change – including guidance on joining techniques that support disassembly, repairability and recyclability.

“Transparency on CO₂e and circularity across the entire lifecycle, even at component and sub-component level, is enormously helpful in identifying high-impact levers”, says Christian Neese, Project Manager Miele.

Design for Circularity in Practice

As a showcase, the Miele design study VOOPER, a circular cordless vacuum cleaner, illustrates how ‘Design for Circularity’ may look in practice: joining concepts, modular construction and material decisions work in unison to increase circularity and longevity. The VOOPER was presented at IFA 2024 and serves in the showroom as a conversation starter and learning object.

Transfer to processes and scaling

The next step is scaling into practice: the recommendation and material overviews will be integrated into standard workflows, early-phase reviews and training formats. In parallel, the data foundation will be expanded – CO₂e, circularity, ease-of-disassembly ratings, recycled content proportions, typical quality variations and cost trajectories – to further refine comparisons. Further pilot projects across different product groups will deepen insights, for example on ease of disassembly versus service life or recycled content versus mechanical performance.

Guidelines for circular product design

In the spirit of Design for Circularity, specific guardrails will be refined: preferred joining techniques (e.g. mechanical (screw/plug) rather than adhesive bonding), modular architectures, defined dismantling pathways and spare parts strategies that enhance repairability. Complementary metrics for impact measurement will be developed – CO₂e reduction per appliance, circularity levels, repair rates, material recovery rates – alongside regular monitoring.

Miele establishes the foundation for knowledge-based sustainability in product development, guidance without pre-empting decisions: transparent enough to enable swift action, whilst simultaneously flexible enough to balance technology, costs and performance within the project scope. The VOOPER shows an approach for highly sustainable products – and upcoming pilot projects will further refine it. In this way, a development routine is gradually established in which sustainability is not an add-on, but an integral part of good engineering.