Datenfabrik.NRW: How CLAAS and Schmitz Cargobull are bringing AI into the factory floor

A shortage of skilled workers, high quality requirements and the pressure to produce more efficiently: These challenges are coming to a head in many industrial companies. For four years, the it’s OWL project Datenfabrik.NRW has been working on bringing digital, data-based solutions and artificial intelligence out of the test phase and into operation. The results now show how digital data models, networked systems and AI are changing everyday production: 51 applications have been created in the lighthouse factories of CLAAS and Schmitz Cargobull – from shift planning and digital assistance systems to quality assurance. The companies presented the solutions and findings from the project to over 140 visitors at the ‘Datenfabrik.NRW Experience Day’ at Schmitz Cargobull.

The leading-edge cluster it’s OWL has implemented the project together with the companies CLAAS, Schmitz Cargobull, NTT DATA Business Solutions, Duvenbeck Kraftverkehr and MotionMiners as well as the Fraunhofer Institutes IEM, IML, IOSB-INA and IAIS. With a total volume of 14.5 million euros, including 9.2 million euros in funding from the state of North Rhine-Westphalia, the data factory is one of the largest initiatives for applied AI in Germany.

“Datenfabrik.NRW is a beacon for our industrial state of North Rhine-Westphalia. It brings artificial intelligence directly into the factories where value is created. Digitalization strengthens our SMEs and makes our business location future-proof and competitive. AI supports employees, makes work safer and easier to plan. This is how we combine competitiveness with good, sustainable jobs in our state,” says Mona Neubaur, Minister for Economic Affairs, Industry, Climate Protection and Energy of the State of North Rhine-Westphalia.

Industry under pressure: AI is becoming part of everyday life

Schmitz Cargobull and CLAAS draw a positive conclusion.

“With Datenfabrik.NRW, we have created a practical basis for the use of digitalization and AI in production. The project sets new standards in data-driven production planning and control and also serves as a blueprint for future smart factory initiatives within our organization. The positive feedback from industry, research and politics confirms that we are on the right track – not only for Schmitz Cargobull, but also as a source of inspiration for other industrial companies,” emphasizes Dr Günter Schweitzer, COO of Schmitz Cargobull. “I am convinced that AI is here to stay.”

“Projects like ‘Datenfabrik.NRW’ are essential for the competitiveness of the location, four years of Datenfabrik have shown that digitization is concrete, tangible and worthwhile with real benefits. Industry 4.0 has been taken a step further: AI forecasts enable predictive maintenance and help to control machines and systems more efficiently and reduce downtimes. Pilot projects such as Datenfabrik.NRW provide concrete solutions that are being transferred to series production. Networking production and logistics reduces costs, strengthens competitiveness and ensures sustainability,” says Jan-Hendrik Mohr, CEO of CLAAS. “Thanks to the cross-company collaboration in the consortium, we have managed to achieve something great together and put 30 use cases into practice at CLAAS alone. Internally at CLAAS, our Digital Innovation Team continues to drive the topics forward with motivation.”

“With the data factory, we are taking AI out of the pilot phase and into production. It is not only important that solutions work in two lighthouse factories, but that methods and structures have been created that many companies can adopt – this is precisely our mission as it’s OWL,” says Prof. Dr. Roman Dumitrescu, Managing Director of it’s OWL.

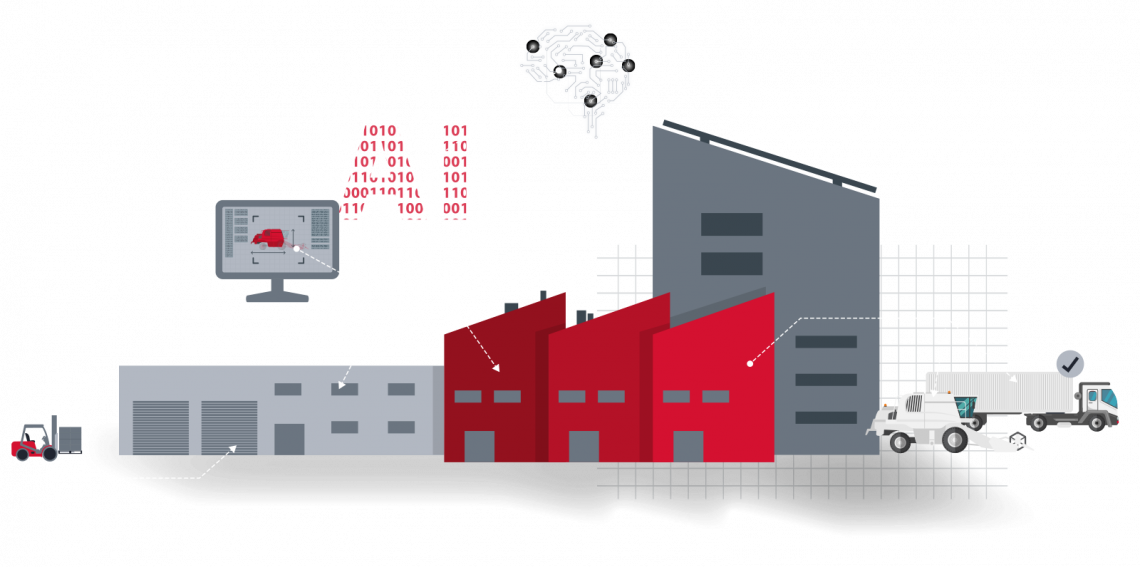

A holistic approach: How Schmitz Cargobull is rethinking digital production planning

The Westphalian town of Vreden shows how profoundly digital technologies and artificial intelligence are changing industrial practice. Schmitz Cargobull is investing over 50 million euros in the expansion of production capacity for refrigerated trailers and box trucks at the site there – a clear commitment to innovative strength “Made in NRW”.

This major project is accompanied by a digital innovation push that sets new standards. As part of Datenfabrik.NRW, the company has fundamentally rethought the planning process and addressed the challenges of modern manufacturing systems with a holistic digital approach: Virtual factory planning, AI-supported analysis and intelligent workplace design interlock seamlessly.

A key result is the development of a digital factory model as a common database (“single source of truth”). This model enables consistent planning across different tools and creates a common database for all parties involved. This is supplemented by the AI-supported processing of 3D point clouds from scans that are integrated directly into existing planning systems.

Traditional workplace design is also undergoing a digital transformation: cardboard workshops, in which workplaces are usually recreated using cardboard models, are now taking place virtually – efficiently, collaboratively and error-resistant. Planning results can thus be secured in digital environments, which speeds up implementation and minimizes planning errors. Intuitive layout tools and motion mining technologies – processes that analyse movement data – have also been used to analyze and optimize existing workstations.

“The results impressively demonstrate how digital technologies are transforming industrial value creation – in a practical, scalable and forward-looking way,” says Lukas Ptock, Project Manager of Datenfabrik.NRW at Schmitz Cargobull.

From highlighters to generative AI: CLAAS relies on digital assistance in assembly

Combine harvester production at CLAAS in Harsewinkel is characterized by high variance and low quantities. For the employees, this means that they have to memorize a lot of complex work content. Before the project, they only received paper lists on which the relevant variants were marked with highlighters. Technical changes had to be made manually in production on a regular basis – a cumbersome process that was time-consuming and error-prone. This made it particularly difficult for new employees to get started.

In the Datenfabrik.NRW project, CLAAS therefore developed a worker assistance system that initially digitally mapped the sequence of orders, color-coded them and displayed them via a web-based interface. But that was just the beginning. Further information was added step by step: product audit data, 3D models, technical changes and assembly instructions are now provided automatically.

The system is directly networked with the factory via an IIoT (Industrial Internet of Things) connection. Automated guided vehicles digitally locate their position within the hall and automatically report back orders. This means that employees always see the right information at the workplace. Changes are indicated by a traffic light signal and audible alerts, helping to avoid errors.

“In this use case, we are guided by the familiar 6Rs from logistics: the right information, at the right time, in the right quantity, in the right quality, in the right place and with the right effort. The important thing is not to flood anyone with information, but to provide targeted support,” says Timo Westerbusch, Project Manager Data-Driven Manufacturing at CLAAS.

The system was developed to be scalable from the outset. Today, it is already in use at 120 workstations in Harsewinkel and the international roll-out is in preparation.

The topic of artificial intelligence is not left out either. At the same time, CLAAS is testing the integration of a chatbot based on generative AI, i.e. a technology that can generate speech independently. In future, this assistant will provide assembly information as required. Initial tests, such as the automated provision of warning stickers, are proving promising.

“It is important to us that all the information displayed in our system is reliable. If an error occurs due to incorrect data, acceptance of the system may be lost. That’s why we attach particular importance to intensive testing of our results before we integrate them into the productive environment,” adds Timo Westerbusch.

51 applications, one lesson: AI must not remain a pilot

The data factory has shown that AI applications do not have to get stuck in trials, but can also be implemented. 51 use cases in real factories and a clear process model for the transfer turn individual projects into recurring solutions that can also be transferred to other companies.

Radiance beyond the locations

The KI.NRW competence platform also emphasizes the importance: “In Datenfabrik.NRW, AI systems are used directly in factory planning, production, logistics and enterprise architecture. The partners show: AI is not a dream of the future, but is already a great help for companies today. We see the project as a strong transfer from research to application,” says Dr. Christian Temath, Managing Director of KI.NRW. KI.NRW has included Datenfabrik.NRW in its flagship initiative, supported the visualization of the project results and networked project staff with AI experts from other fields. KI.NRW flagships are highly innovative and application-oriented AI projects in individual and joint projects from various sectors, such as retail, production, trade and healthcare.

From lighthouse to broad reach: How it’s OWL reaches SMEs

In future, it’s OWL will ensure that the approaches developed do not remain in pilot plants, but can be used by SMEs in NRW and beyond. Together with the partners involved, the technology network is taking artificial intelligence from the concept to the factory floor. Companies can draw on tried-and-tested methods and tools instead of starting from scratch.