it’s Showtime: it’s OWL projects present their innovations to the jury

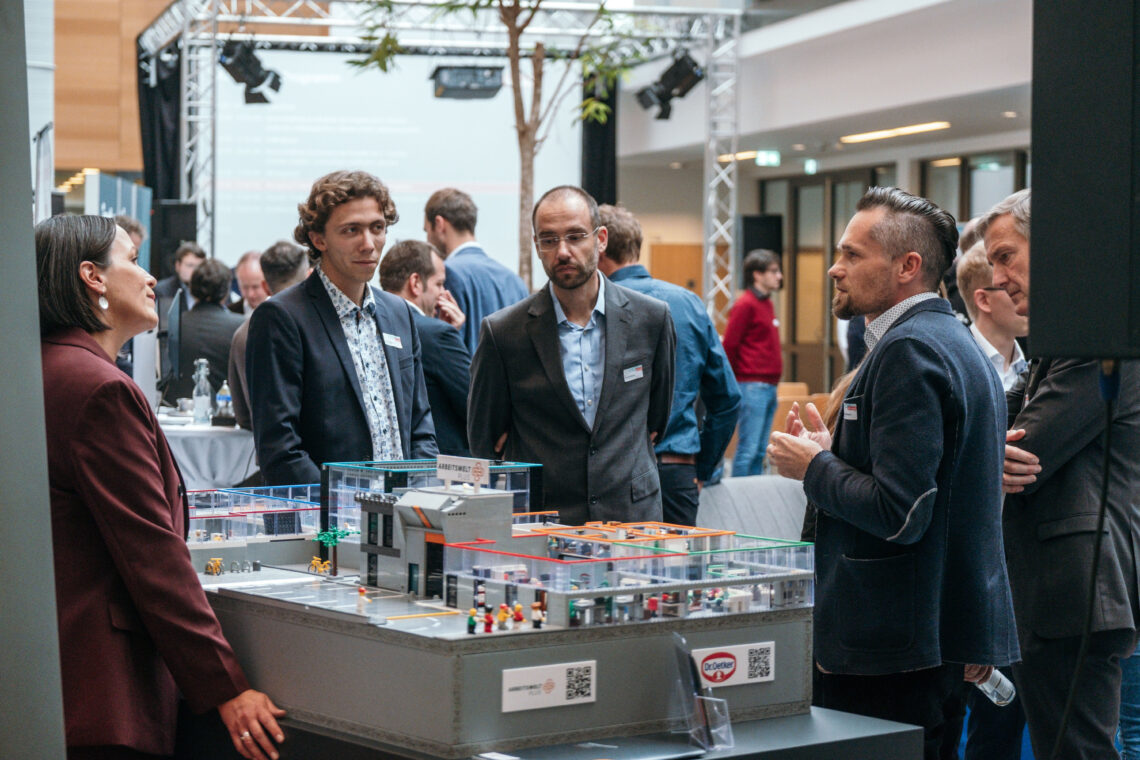

Nine projects, a project volume of around 40 million euros and a whole host of new innovations: At the second edition of ‘it’s Showtime’, selected projects from the Leading-Edge Cluster presented their results to date. With around 100 participants at the Industrial IT Center in Lemgo, the focus was on sustainability, the circular economy, reducing greenhouse gas emissions, green digital twins and artificial intelligence in the world of work as well as in production and logistics.

In pitches and an exhibition, the projects presented themselves to the it’s OWL advisory board and the management of the competence network as well as to representatives of the it’s OWL cluster board. The project managers presented the specific project results and their transfer possibilities for other companies and showed how the results are further utilized in the participating companies. “In our projects, companies and research institutions work together to develop new technologies and solutions to tackle specific industry challenges. At ‘it’s Showtime’, the projects impressively demonstrated the enormous added value they offer for the regional economy. Our companies benefit directly from the latest innovations that emerge from our network,” says Prof. Dr. Roman Dumitrescu, Managing Director of it’s OWL.

it’s OWL projects offer companies sustainable solutions

This is how the project ‘Climate-neutral Business in OWL’ (Climate bOWL) supports companies on their way to optimising their energy efficiency, for example. The kilowatt hour that does not have to be generated does not emit any greenhouse gases and does not incur any costs.

This is where the project comes in. By 2025, the universities of Paderborn and Bielefeld, together with the companies Gea, Miele, NTT Data Business Solutions and Phoenix Contact, will develop an intelligent assistance system that will support companies in reducing their greenhouse gas emissions along the value chain.

In the it’s OWL project ‘ZirkuPro’, Miele, manufacturer of household and commercial appliances, is focussing on the development of sustainable electronics. “For example, Miele wants to give greater consideration to aspects of the circular economy when developing future generations of ovens. The design of components should also make repairs even simpler and more efficient in future,” says Dumitrescu.

Some electronics consist of critical materials, such as rare earths, and their CO2 emissions are often underestimated.

On the way to a data-driven factory of the future

The Datenfabrik.NRW project shows how AI and data can shape the factory of the future. In the project, global market leaders CLAAS and Schmitz Cargobull are working together with NTT DATA Business Solutions, Duvenbeck Kraftverkehr and MotionMiners as well as the Fraunhofer Institutes IEM, IML, IOSB-INA and IAIS to develop a model for a data-driven factory of the future. “In addition to providing insights into a selection of our 50 or so use cases, our offerings from Datenfabrik.NRW provide companies with concrete recommendations on how they can take their first steps in using AI and what they should ideally look out for,” says project manager Stefan Hartmann.

More future viability through resilience

Frank H. Lehmann, member of the it’s OWL advisory board and former site manager of the Mercedes-Benz plant in Kassel, spoke about ‘Resilience as a key factor for sustainable success’ and highlighted how it’s OWL can specifically strengthen the resilience of companies. This includes supporting the development of a future-oriented mindset that enables companies to react flexibly to change. At the same time, it is important to further develop the existing network in a smart way and to expand ongoing projects to include the ability to adapt. Lehmann also advocated setting up new projects with a focus on “Industry.4.resilience” in order to prepare companies even better for future challenges.

More information on the projects

All information on the results of the individual projects and all other completed projects can be found on our website and our innovation platform. These projects took part in it’s Showtime: AI4ScaDa, Arbeitswelt.Plus, Climate bOWL, Datenfabrik.NRW, EcoTwin, ExplAIn, I4.0AutoServ, SUPPORT, ZirkuPro.